Common Centrifugal Pump Problems

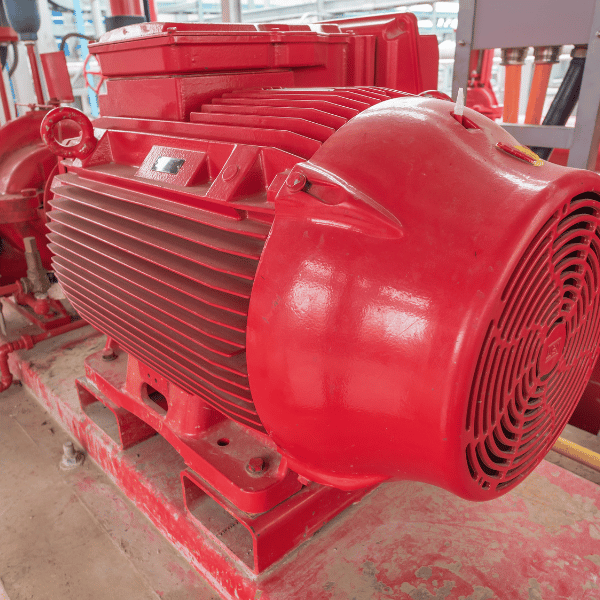

A centrifugal pump is a hardworking piece of equipment used to transport fluids.

A centrifugal pump is a hardworking piece of equipment used to transport fluids. With proper preventative maintenance, these workhorses usually run trouble-free. However, issues can occur.

It’s essential to know the signs of future troubles and nip them in the bud to keep the pump running. For example, some common problems could signal a pump requires maintenance or repair by a plumbing professional.

The pump won’t start

When a pump doesn’t start, the most common culprit is that its fuse has blown or its circuit breaker has tripped. If it’s neither of these issues, look for loose electrical wiring in the electrical panel. Contact a licensed pump repair professional if any wires seem to have lost their connection.

Leaking issues

An adequately maintained centrifugal pump shouldn’t leak. Common causes of leakage are excessive pressure and corrosion. Leaking can be corrected by tightening the joints or replacing their gaskets or seals. However, constant leaking can cause further problems, so they should not be ignored.

Reduced flow

A reduction in the proper flow of fluid could be caused by one or more of these issues:

Worn and leaking gaskets or seals

Incorrect impeller rotation

Open bypass valve

Impeller, pump inlet, or discharge line blockages

Damaged impeller

Operating the pump with a reduced flow could be more efficient and lead to other issues, such as burst pipes or a clogged system shutting down completely.

Overheating

A centrifugal pump that is hot to the touch is typically a sign of a blockage. Overheated pumps will result in a reduced flow of fluid. If left untreated, it could cause further issues, possibly even motor failure.

Blockages that result in overheating are usually found in the suction strainer, recirculation port, discharge line, or valve.

Odd noises or vibrations

Unusual noises and odd vibrations are signs of centrifugal pump problems. When it’s not making the sound it typically makes, it’s crucial to locate the source.

Odd noises usually indicate a foreign object blocking the flow of fluid or damaging the impeller. Another culprit could be that the bearings have failed.

Rattling noises and vibrations could be caused by cavitation. This issue causes powerful shockwaves inside the pump and can cause significant damage.

One should immediately address strange noises and vibrations. If their cause isn’t apparent, consult with a centrifugal pump professional.

Slow re-priming

A properly functioning centrifugal pump shouldn’t re-prime slowly. When re-priming slows down, it indicates a problem with the unit. Typical culprits are improper impeller clearance, leaking gaskets, and clogged recirculation ports.

Don’t wait for the worst

Ignoring centrifugal pump problems will lead to unnecessary damage and eventual system breakdowns. Quick fixes may seem to eliminate the problems, but they could be causing more harm than good. Preventative maintenance performed by a professional pump repair service will keep a centrifugal pump working correctly.

Pump Repair Services has over 32 years of experience providing reliable irrigation pump repair and centrifugal pump repair services in the Orlando area. Our extensive industry knowledge and experience allow us to handle any well or pump-related issues efficiently. 24-hour emergency services available. Call us to book a service and get outstanding service and customer experience.